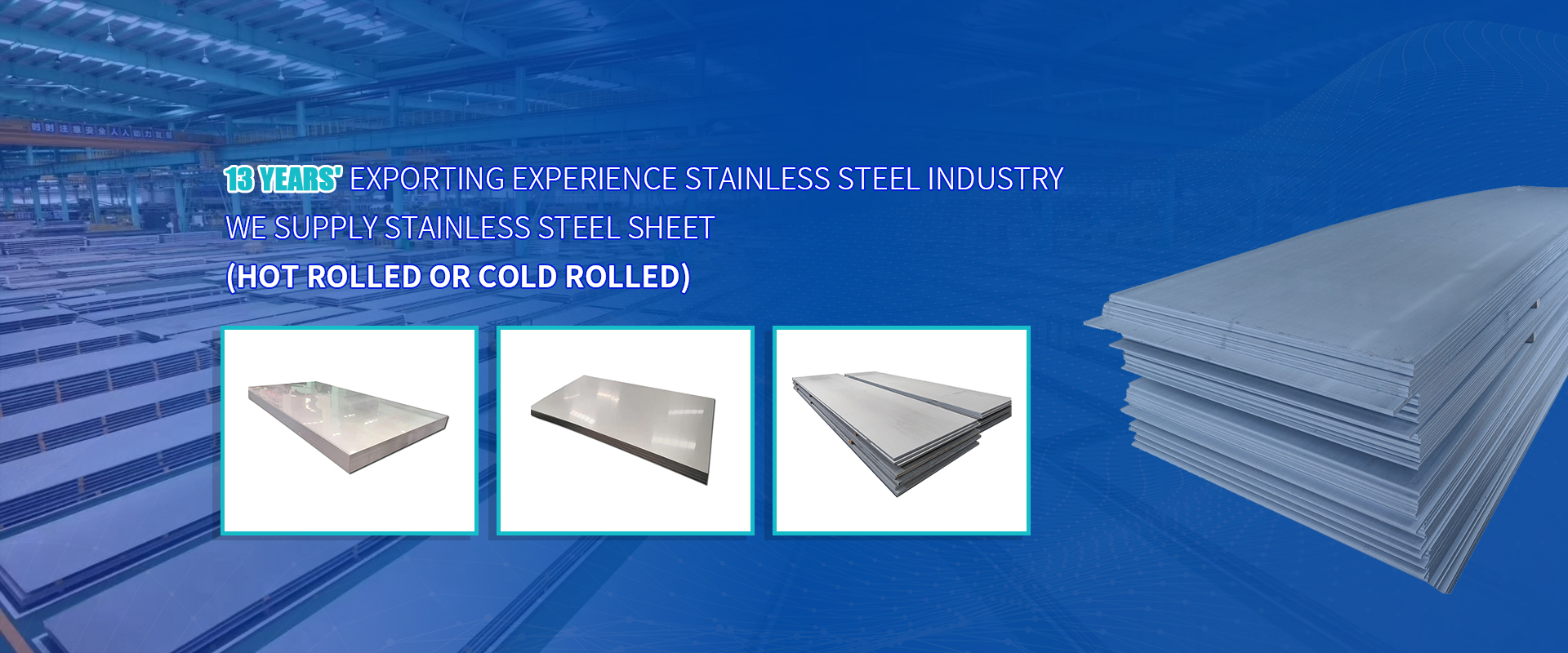

Specialized

Specialized in product

01

Specialized

Specialized in product

01

Quality

Safe and durable

02

Quality

Safe and durable

02

OEM & ODM

The shape of custom

03

OEM & ODM

The shape of custom

03

Service

First-class service

04

Service

First-class service

04

DIN EN 1.4301 stainless steel (x5crni18-10) is a traditional austenitic stainless steel with good resistance to atmosphe···

Characteristics: due to the addition of Mo, its corrosion resistance, atmospheric corrosion resistance and high-temperat···

No.1 SurfaceProcessing type: hot rolled, annealed, deoxidizedState characteristics: rough, matteMain contents: hot rolle···